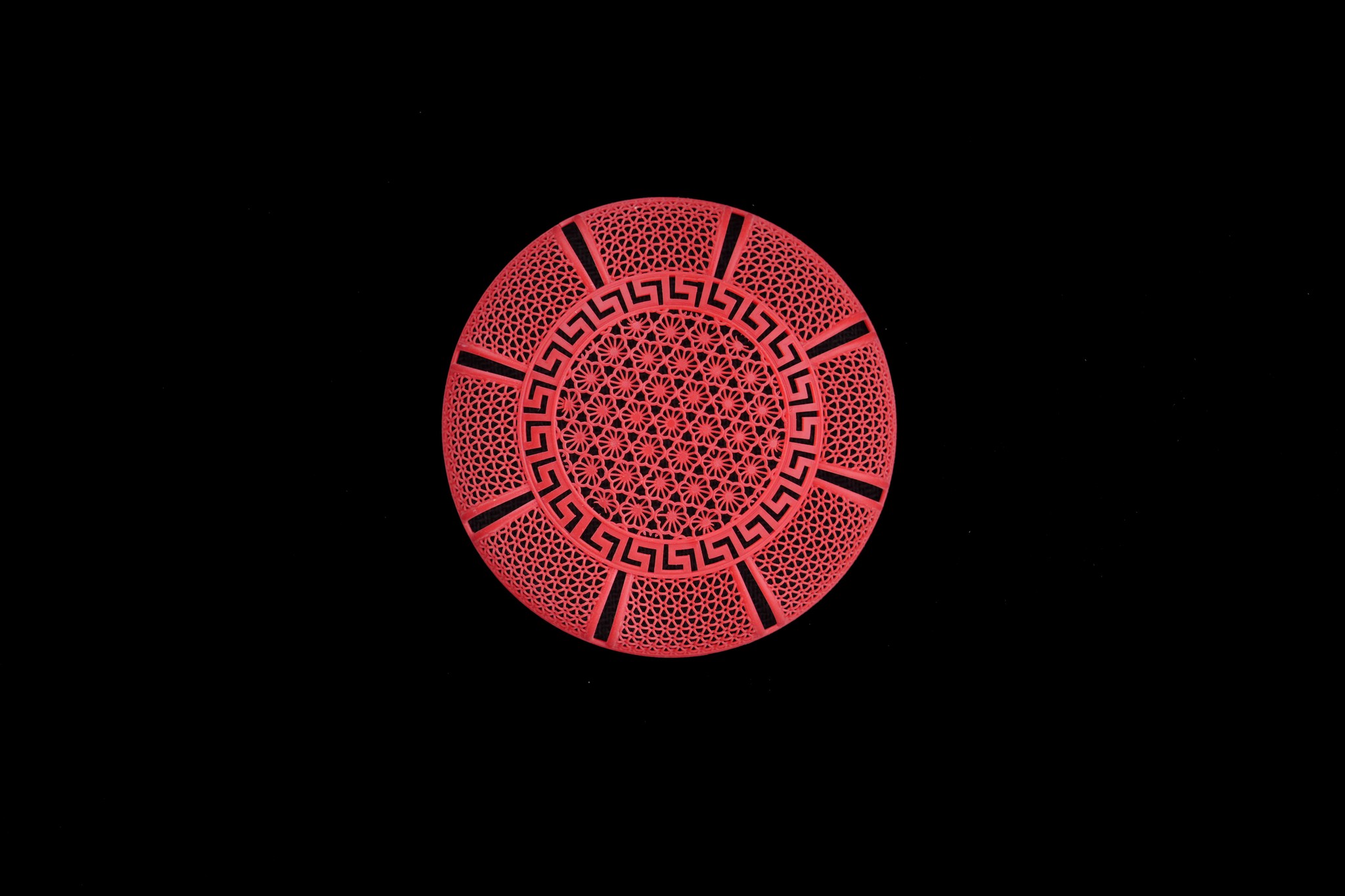

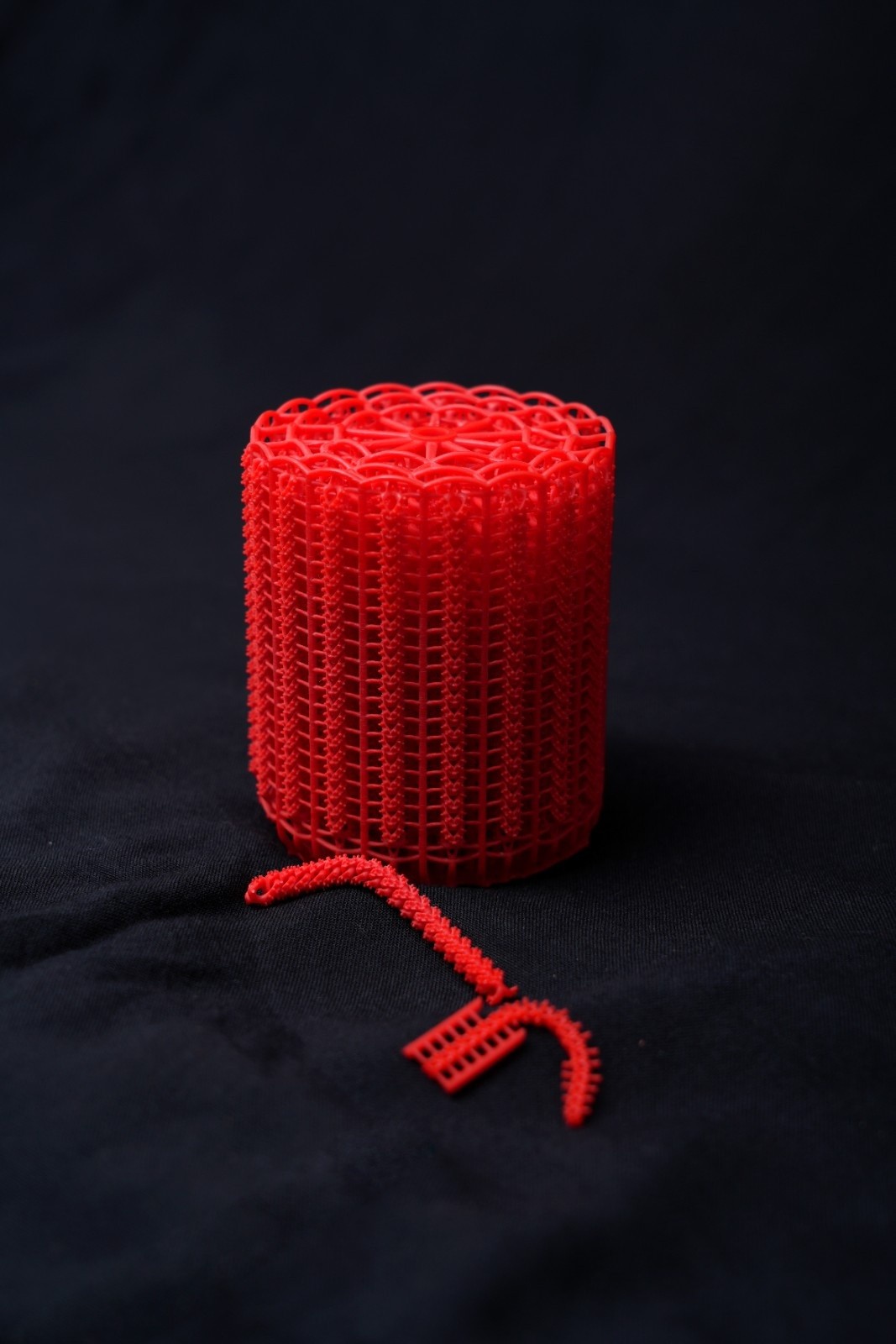

Red: DC6823 / DC444

D3D Resins - latest innovative resin

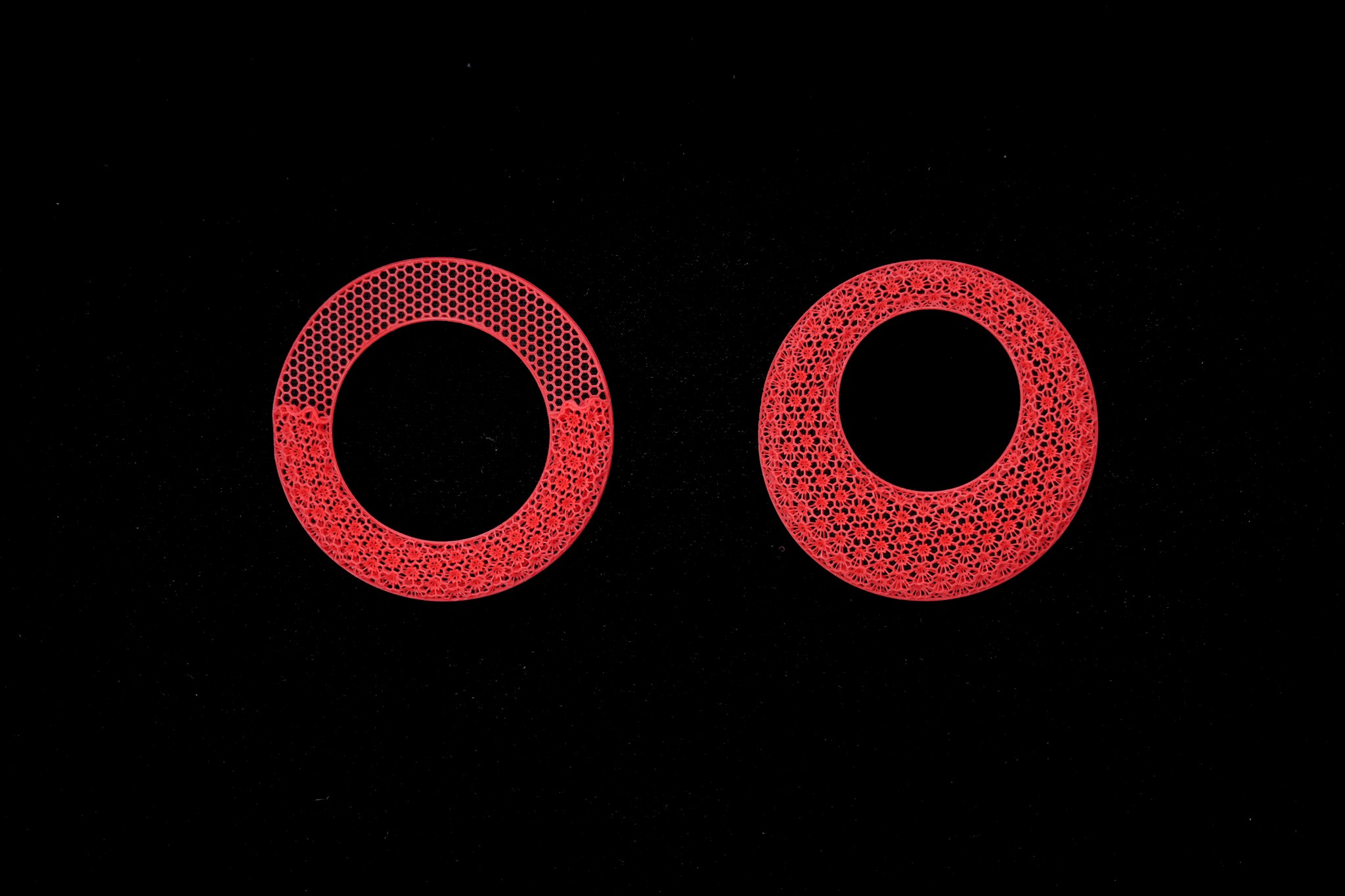

DC6823 / DC444 - is a specially developed direct casting resin for micro pave and tight chains with minimal gap between 2 links.

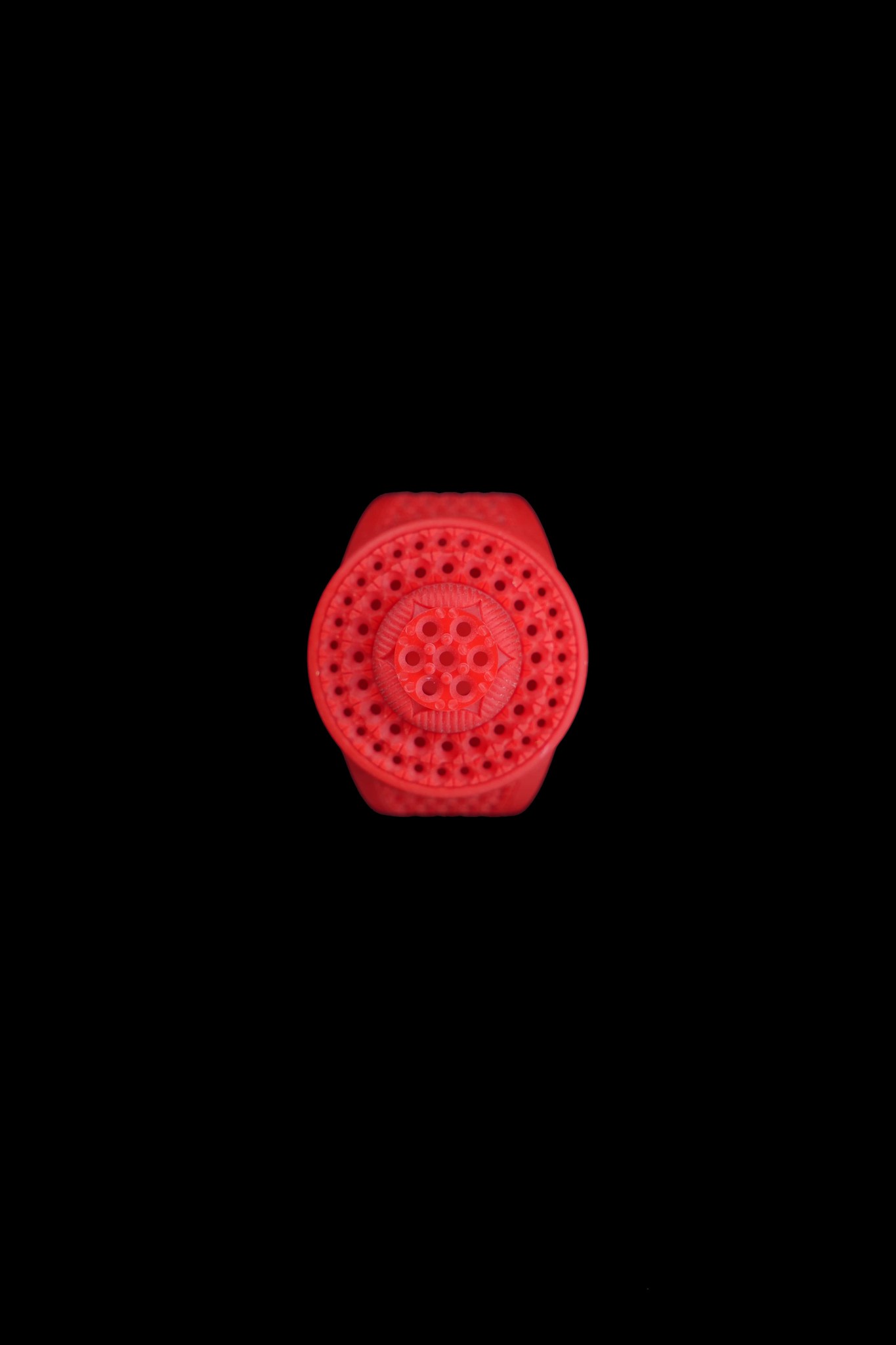

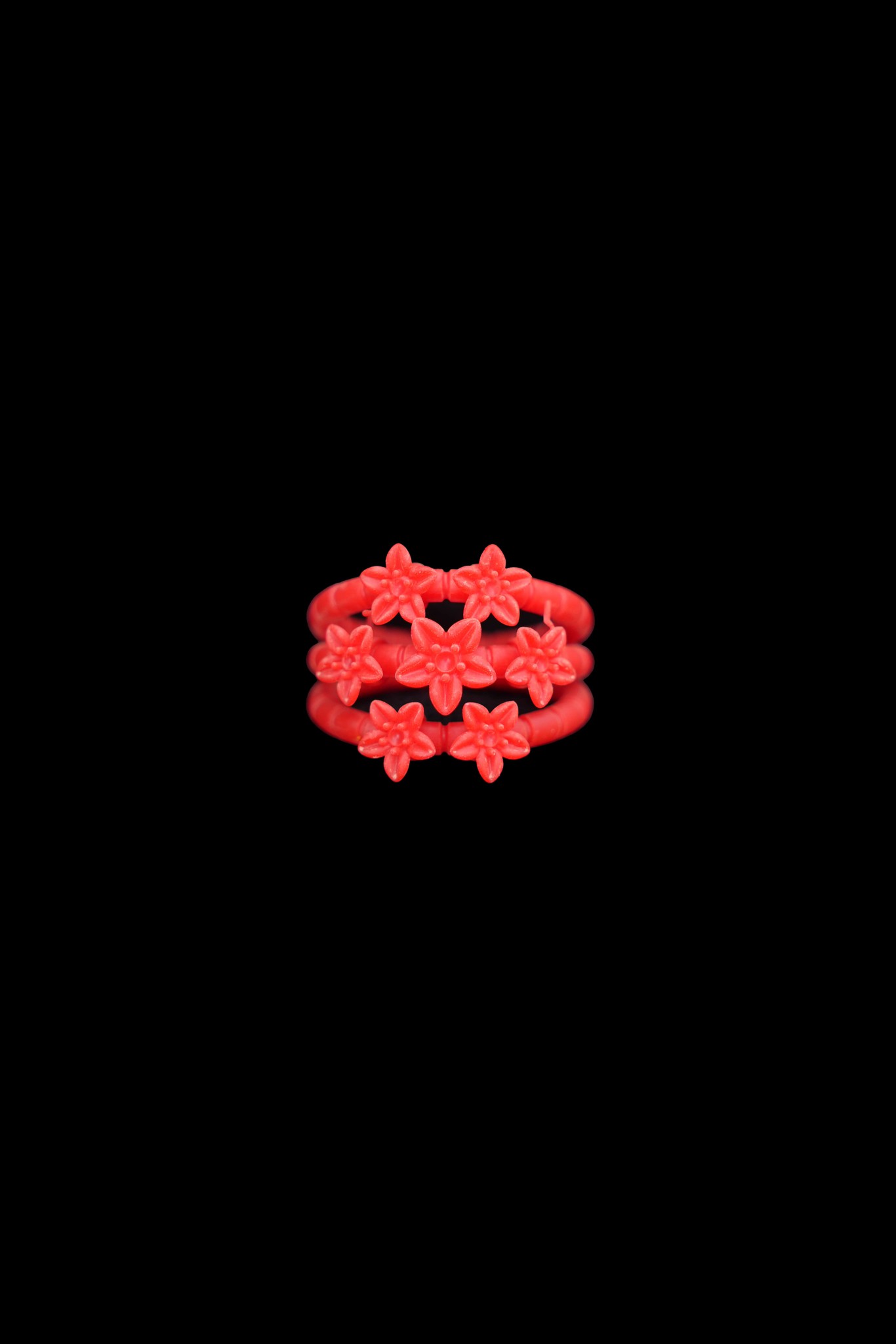

This latest category of 3D casting resins can offer perfection even in the most intricate designs – with this resin, you can achieve gaps between links that are as minute as 0.06mm. This red resin can give you not only super sharp edges to create unique jewellery designs, but also ensures top quality with every casting.

Features :

Achieve gaps between links of chains / bracelets of as low as 0.06 mm (depending on your 3D printer resolution)

Achieve super micro pave with gaps between 2 prongs as low as 0.08 mm

Sharp edges

Top casting quality

Easy burnout

Can use normal investment powder

Shrinkage less than 1%

Properties :

Tensile strength: 25 Mpa

Flexural strength: 45 Mpa

D shor hardness: 64

Viscocity: 660 to 750 Mpas @ 24°C

Post Processing Instructions:

Recommended Burnout Cycle :

Step 1

Room Temp to 100°C

Ramp @ 2°C/minute = 30 mins

Hold Time: 3 hours

Total Time: 3 hours 30 mins

Step 2

100°C to 730°C

Ramp @ 5°C/minute = 2 hours 6 mins

Hold Time: 4 hours 30 mins

Total Time: 6 hours 36 mins

Step 3

730°C to Cast Temp

Aprox 30 mins

Hold Time: 1 hour 30 mins

Cast

Total Time: 2 hours 30 mins