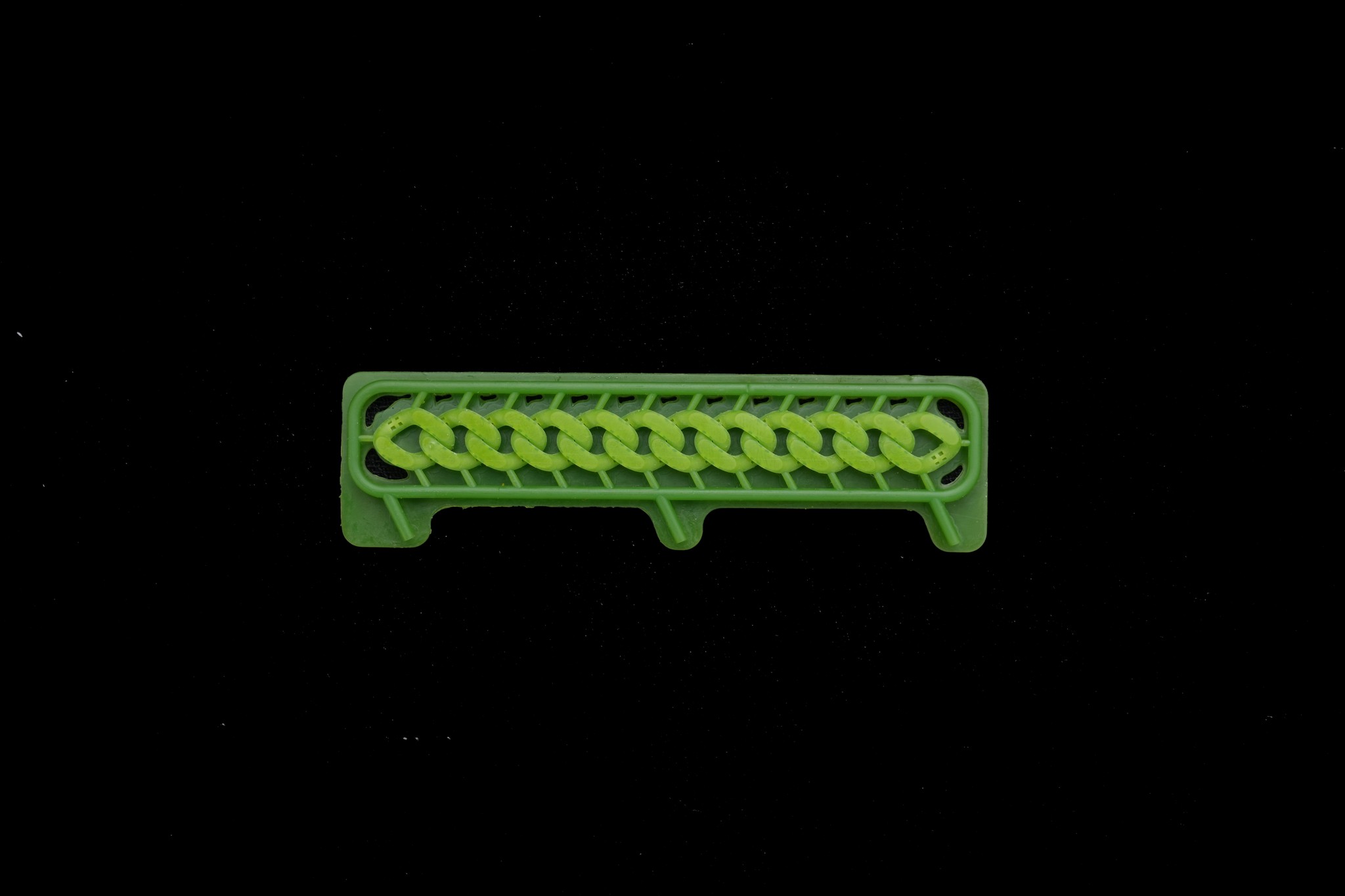

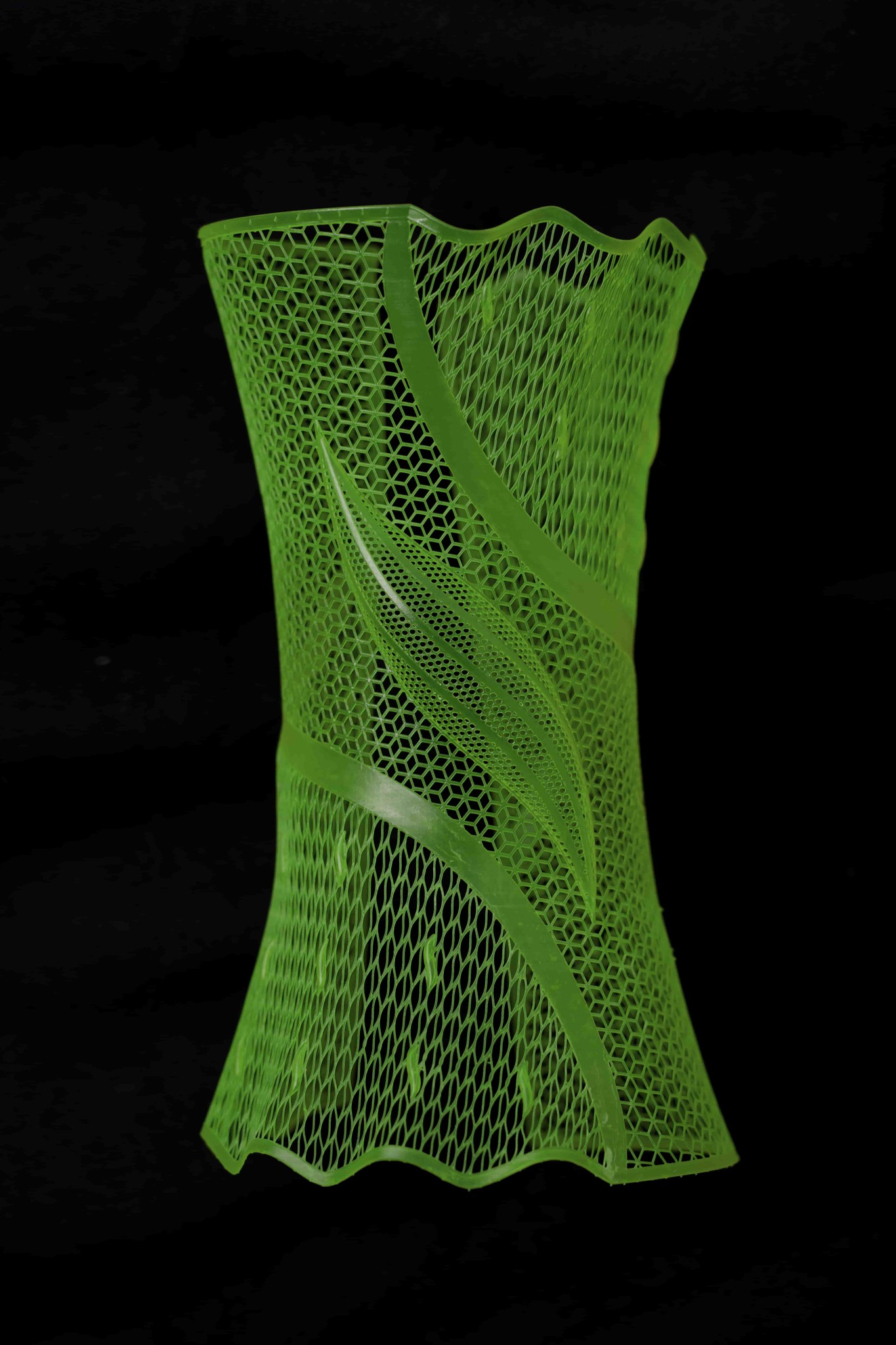

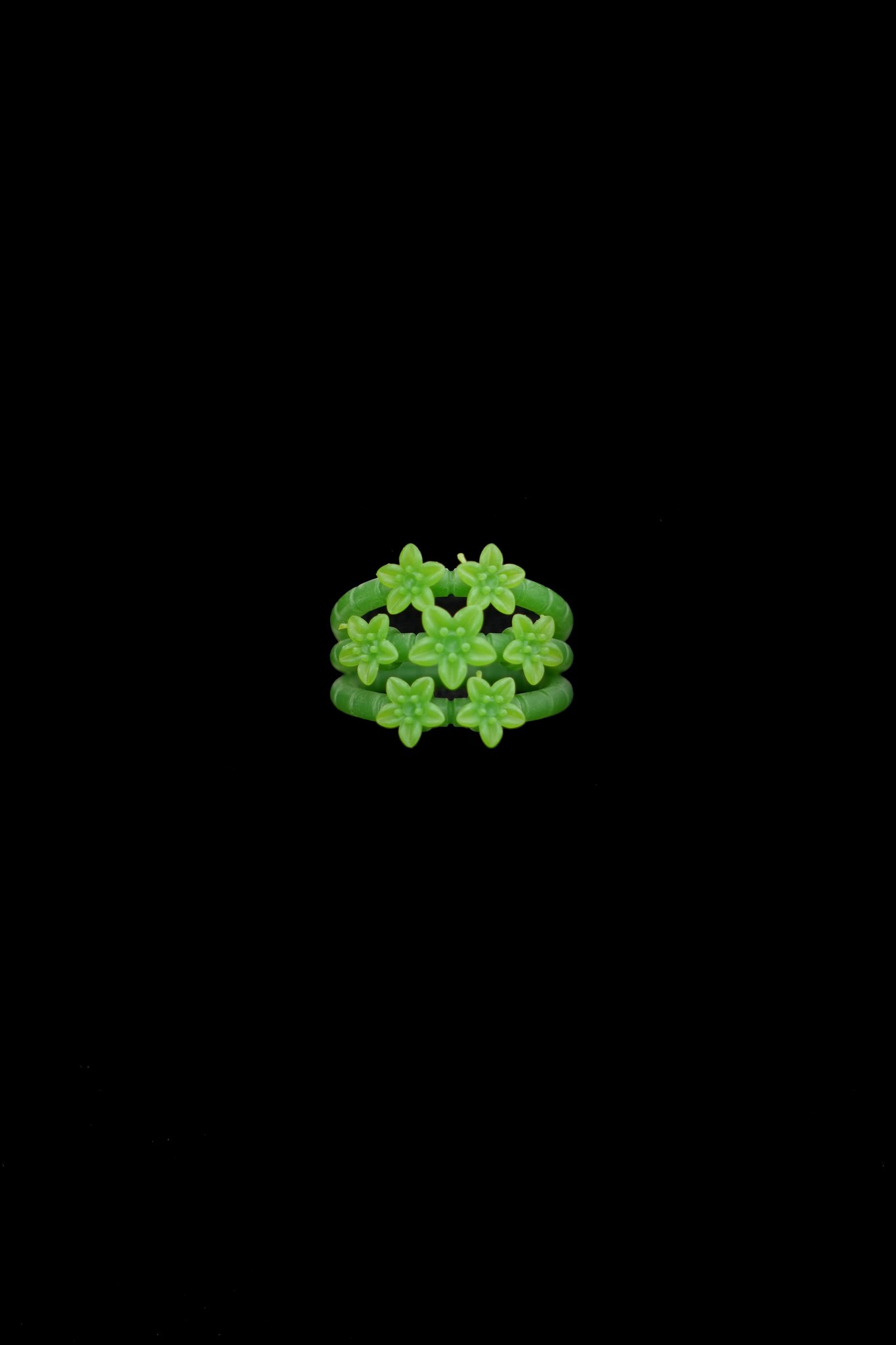

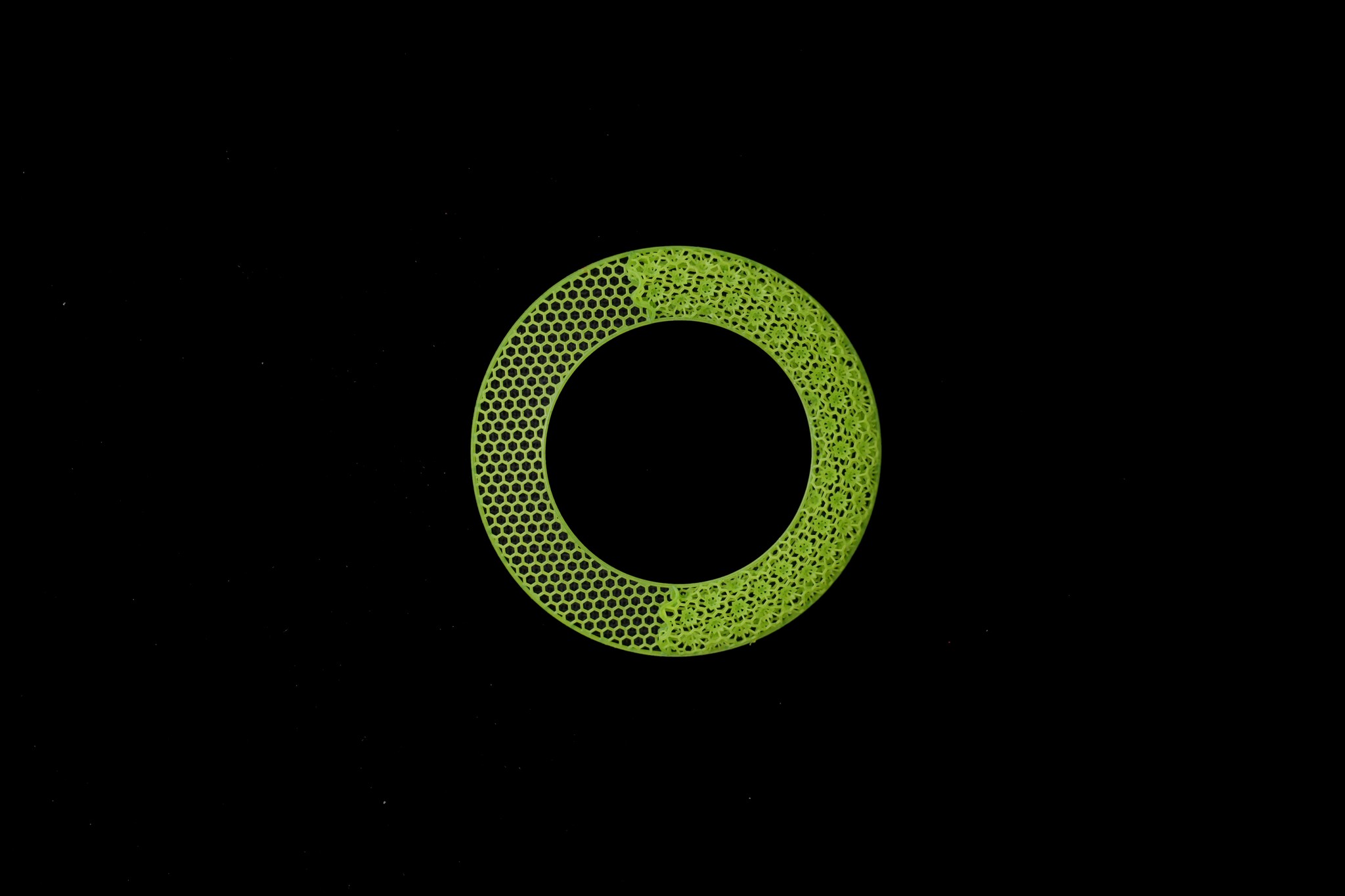

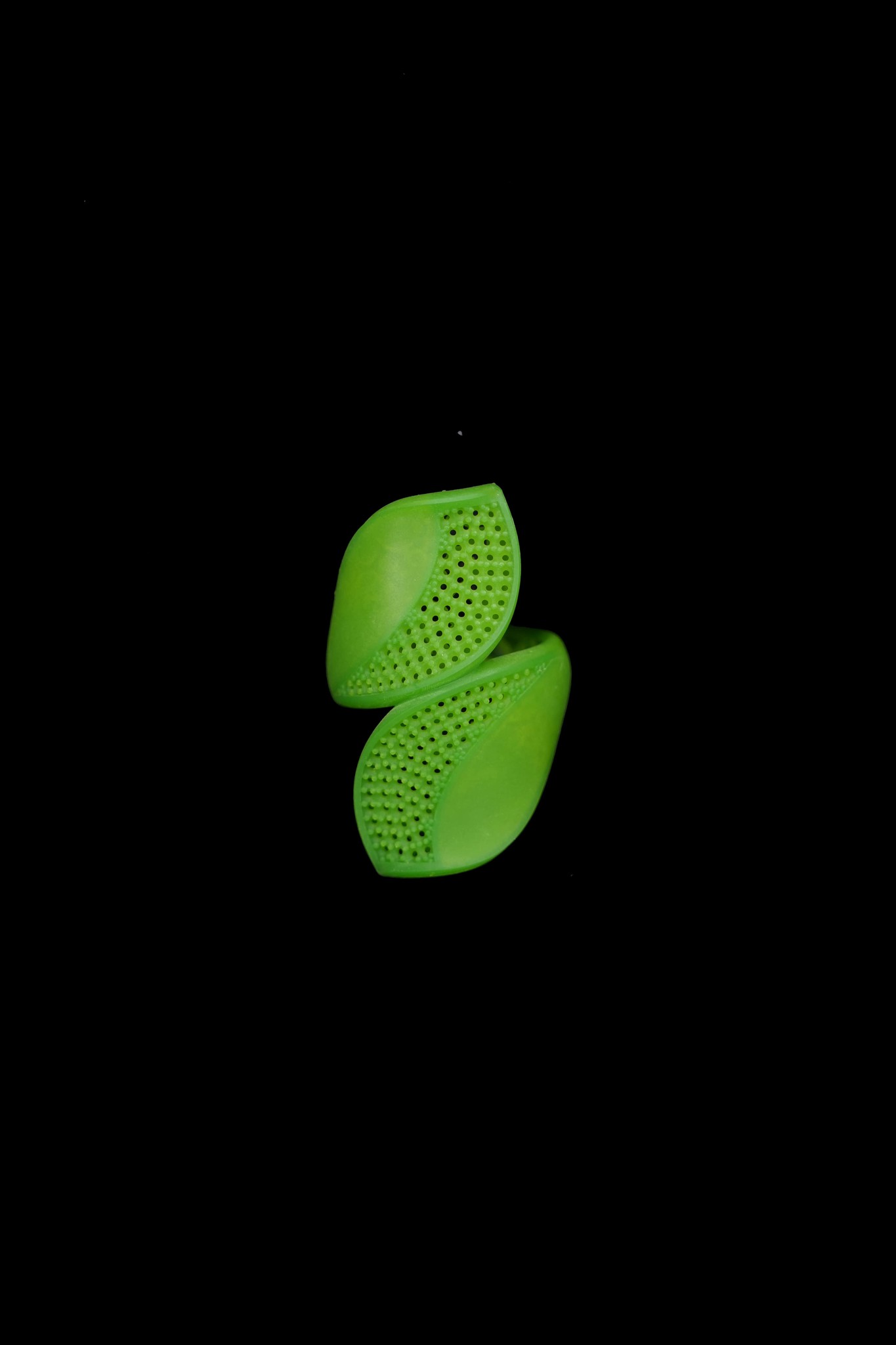

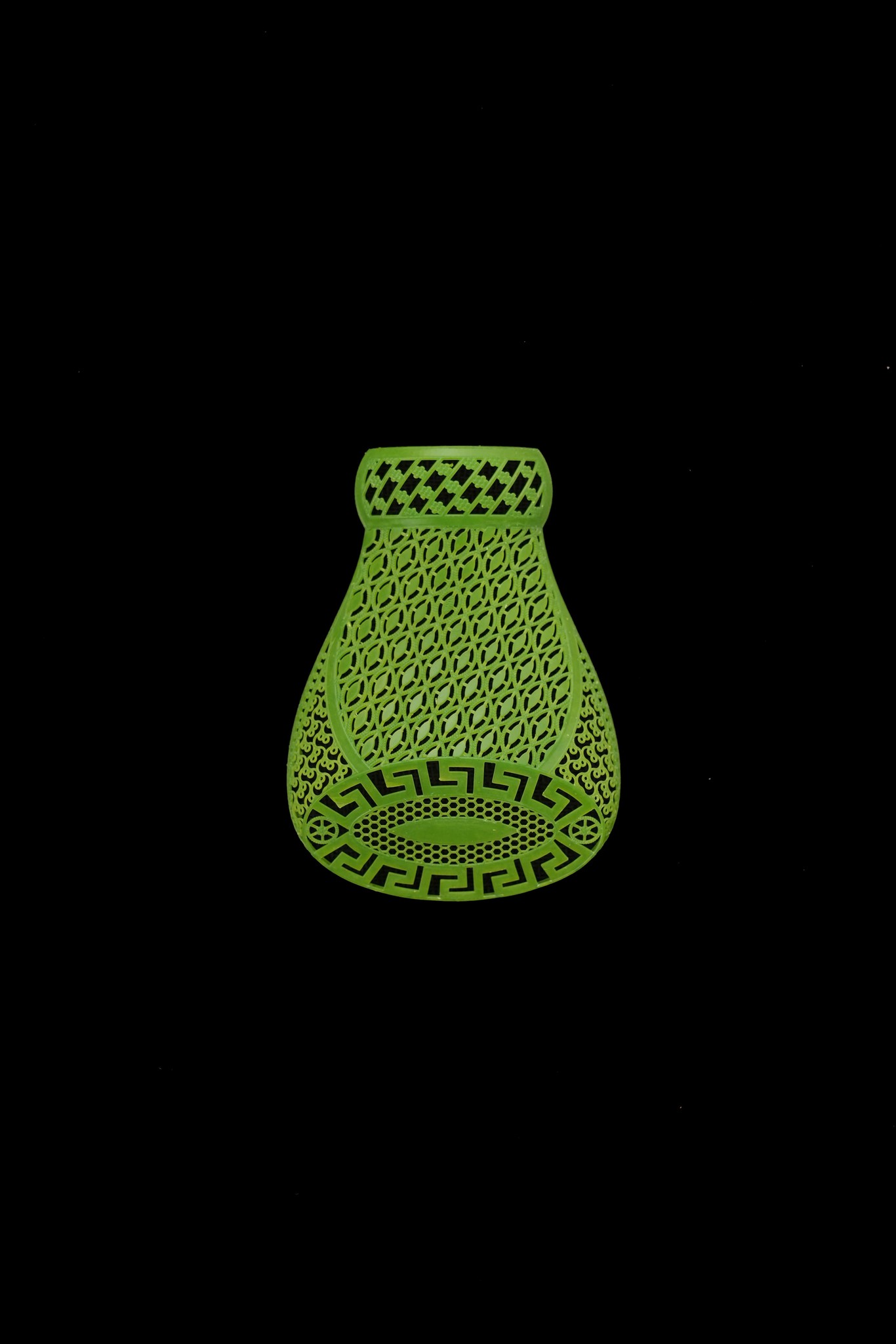

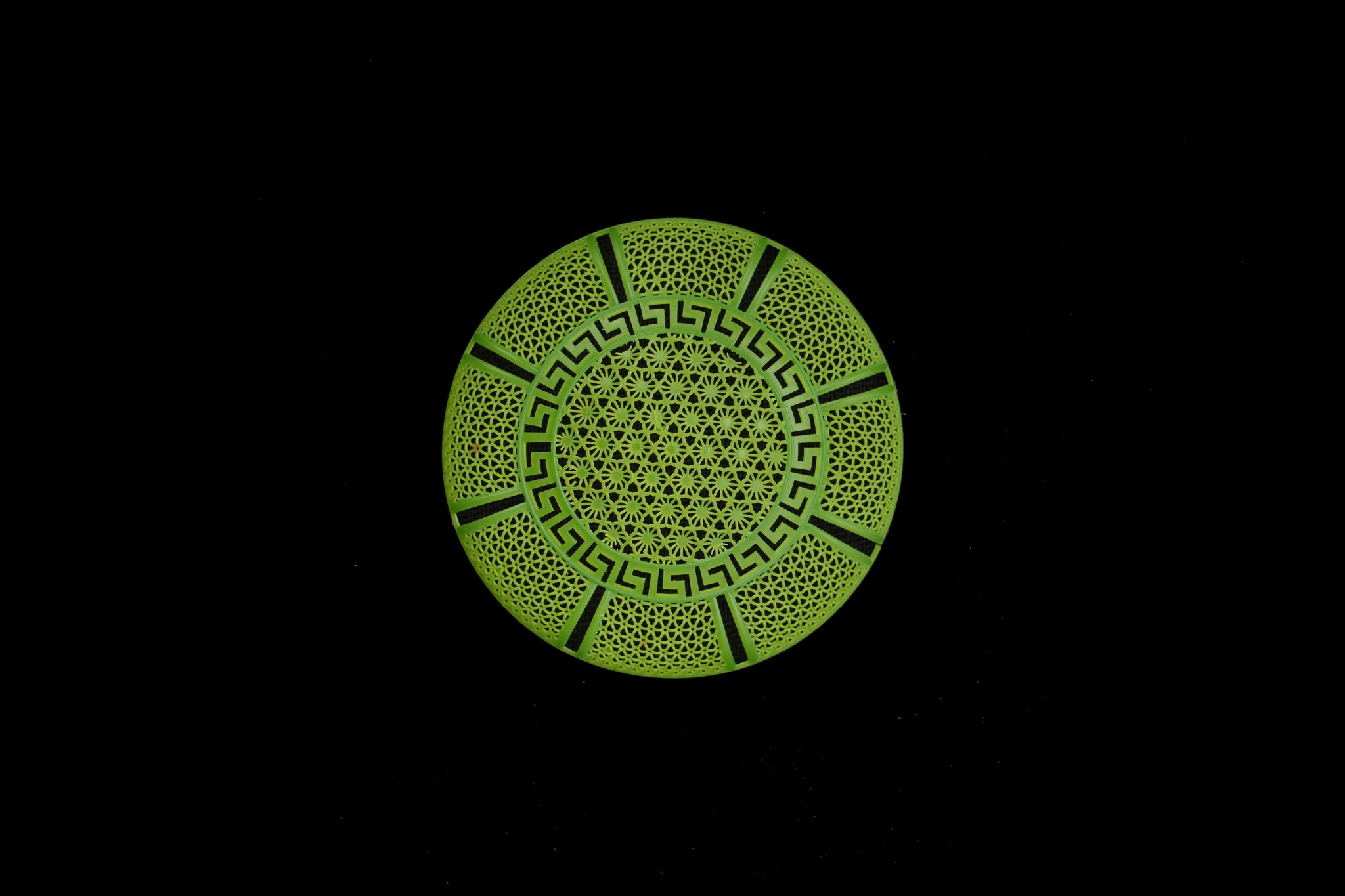

Green: DCGC / DC369-3 / DCGCU

D3D Resins - Universal Resins

DCGC - works only on LCD printers.

DC369-3 - is ideal for the wax setting of stones.

DCGCU - is ideal for high-speed printers like Novafab, Protospeed & RapidShape and can be used on LCD printers as well.

These 3D printing resins can be utilised for a wide range of jewelry designs & offer top casting quality.

Features :

Universal resins for all types of jewellery

Top casting quality

Easy burnout

Can use normal investment powder

Shrinkage less than 1%

Properties :

Tensile strength: 22 to 24 Mpa

Flexural strength: 44 to 48 Mpa

D shor hardness: 60 to 66

Can use normal investment powder

Viscocity: 700 to 800 Mpas @ 24°C

Post Processing Instructions:

Dip in isopropyl alcohol for 1 to 2 minutes until it's mostly cleaned.

Spray the prints with isopropyl alcohol to remove any stuck resin or stickiness

Put prints in a glass beaker 80% full of distilled water & put the beaker in any UV curing oven for 5 to 15 minutes

Dry the prints either (A) with a hair dryer manually or (B) in a heating oven at 75°C for 1 hour or (C) in a vacuum drying oven

Recommended Burnout Cycle :

Step 1

Room Temp to 100°C

Ramp @ 2°C/minute = 30 mins

Hold Time: 3 hours

Total Time: 3 hours 30 mins

Step 2

100°C to 730°C

Ramp @ 5°C/minute = 2 hours 6 mins

Hold Time: 4 hours 30 mins

Total Time: 6 hours 36 mins

Step 3

730°C to Cast Temp

Aprox 30 mins

Hold Time: 1 hour 30 mins

Cast

Total Time: 2 hours 30 mins