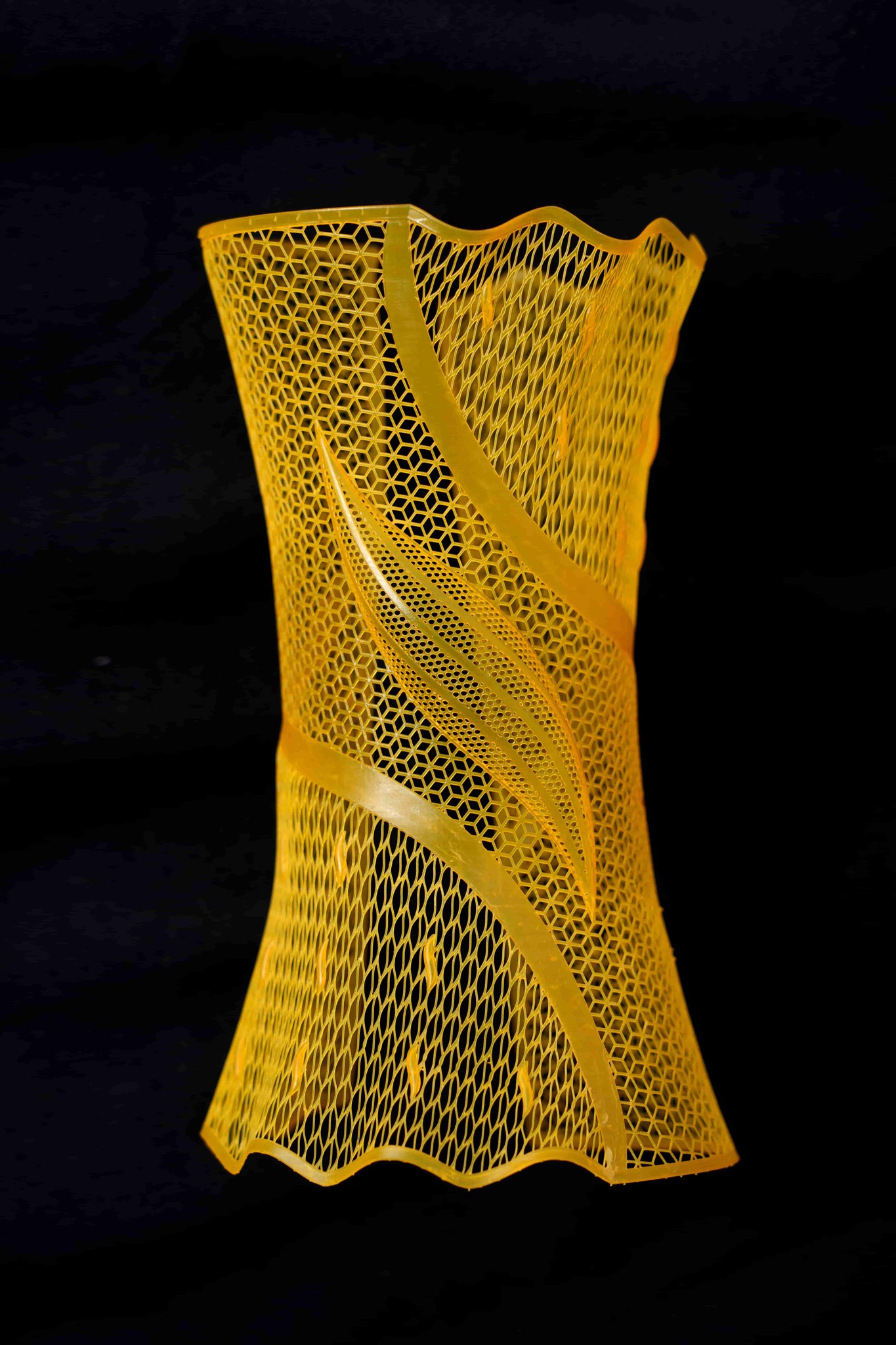

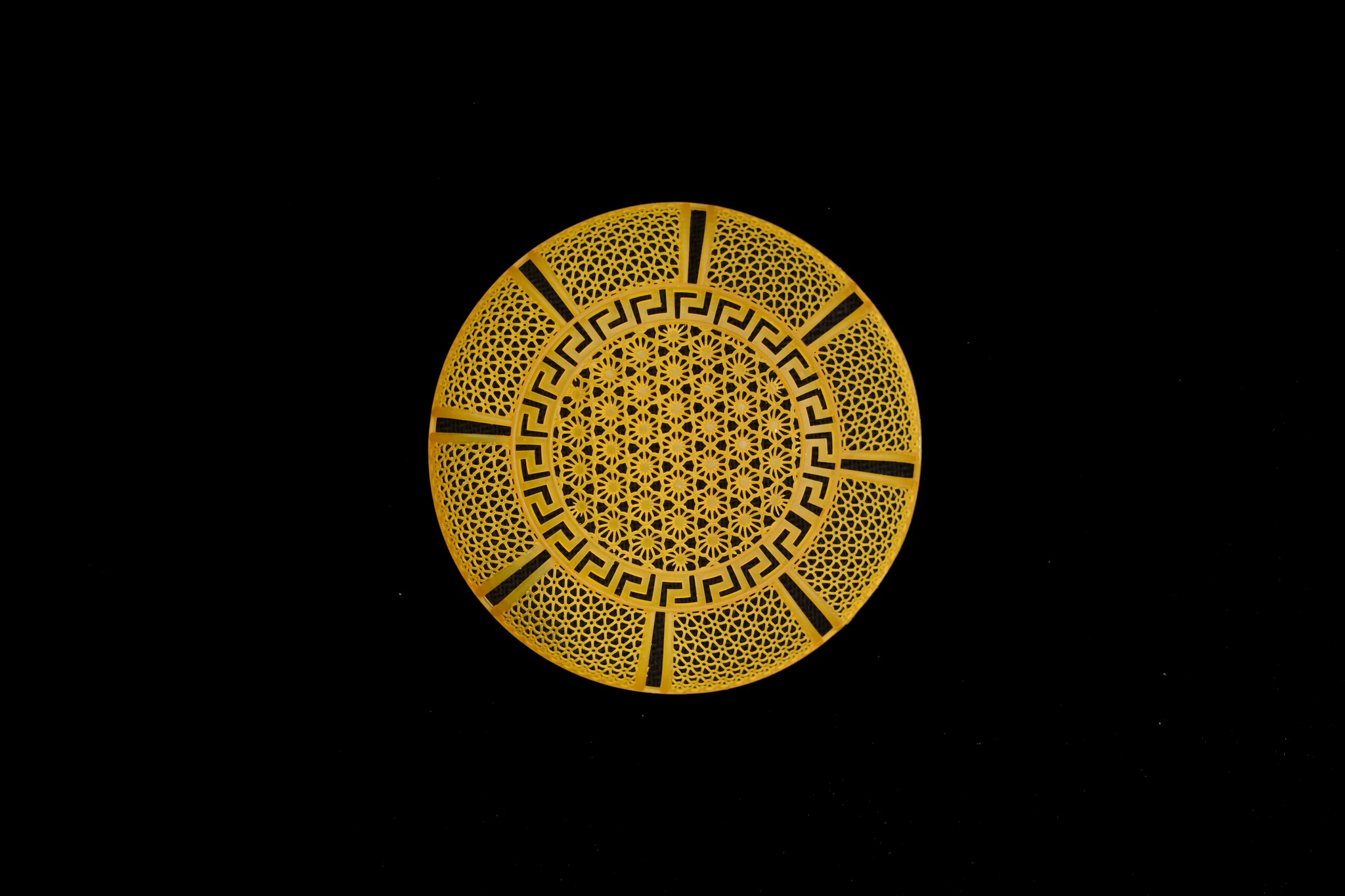

DCDNO Yellow / DCDNR Orange

D3D Resins - highest selling Resin

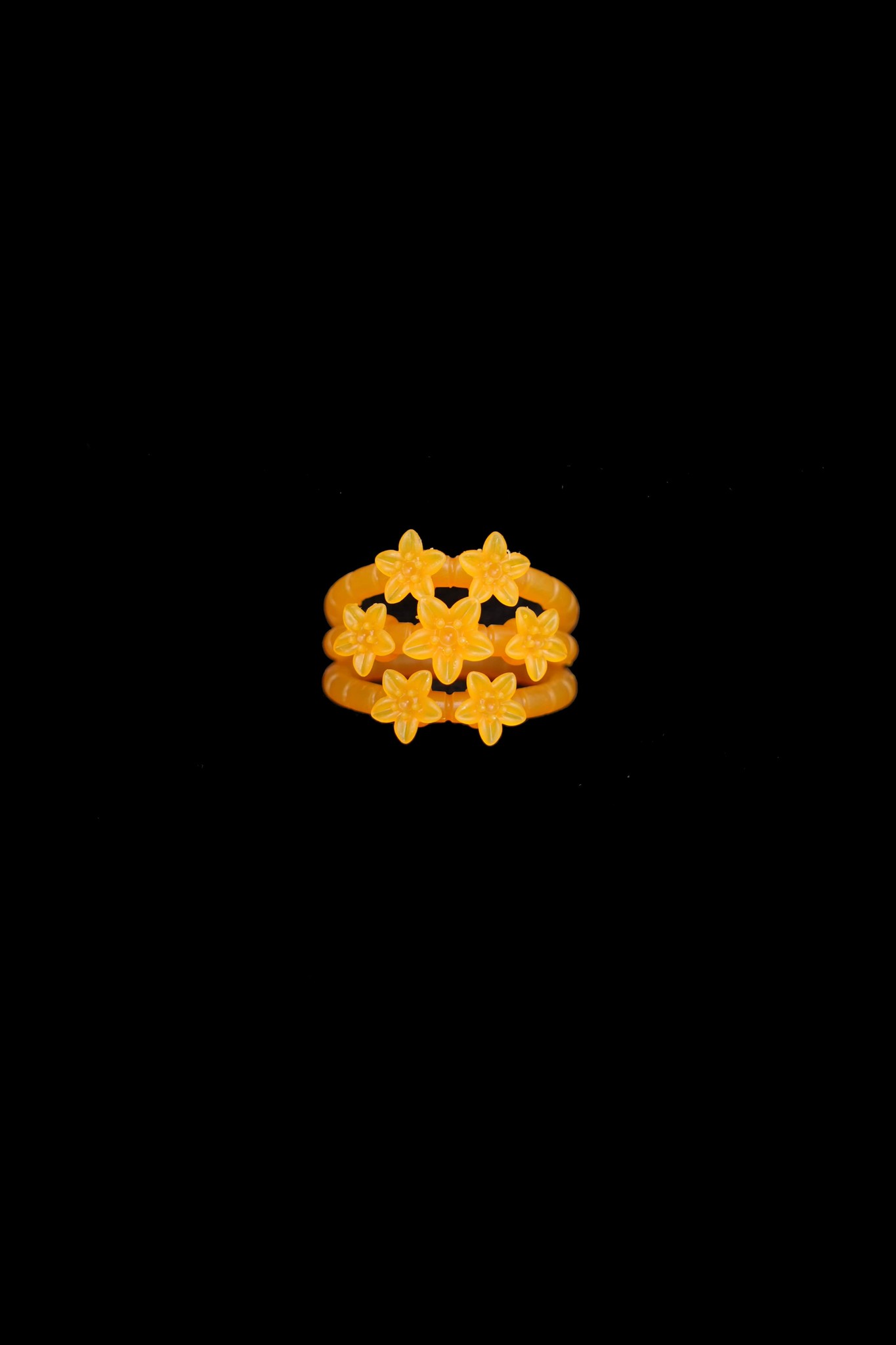

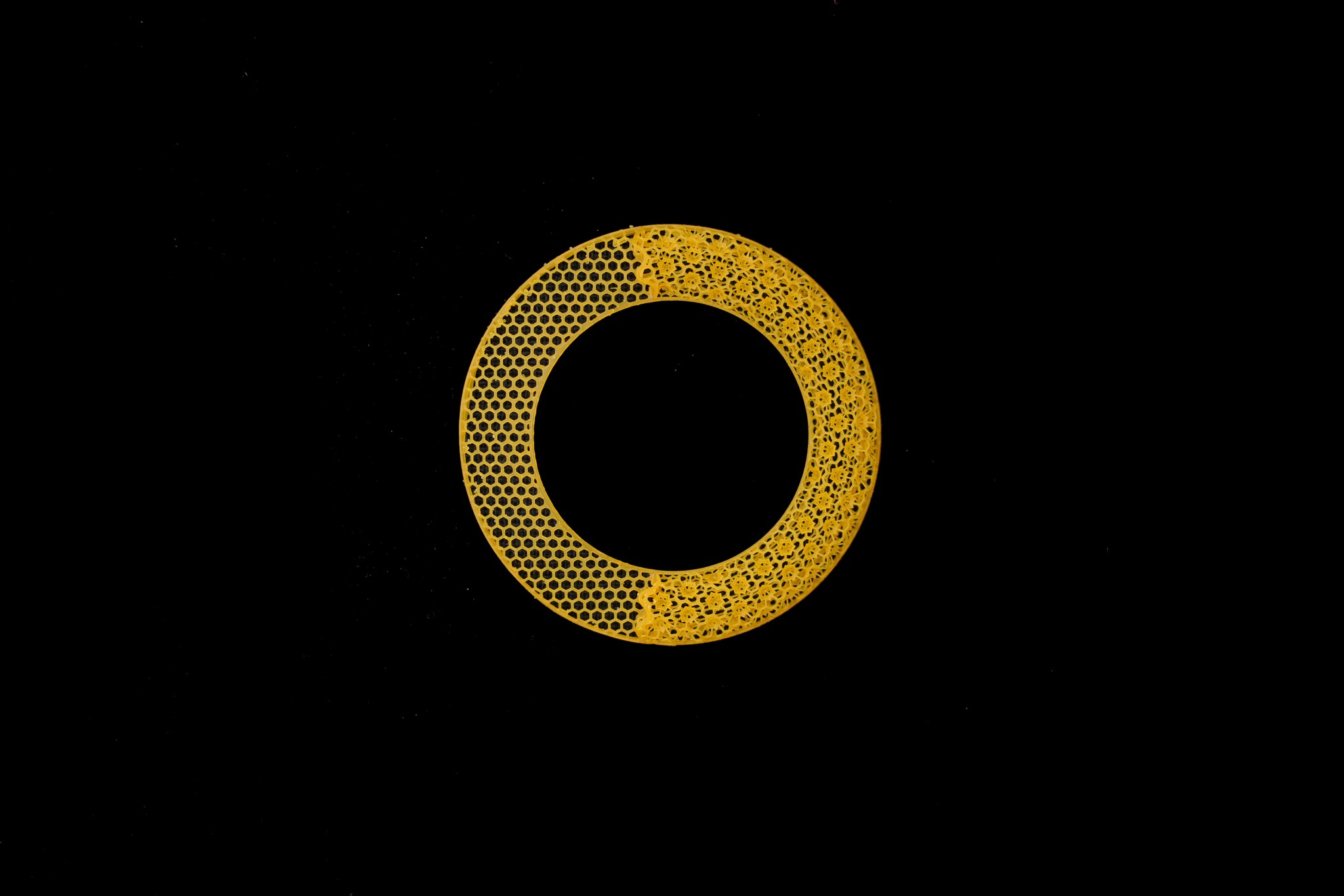

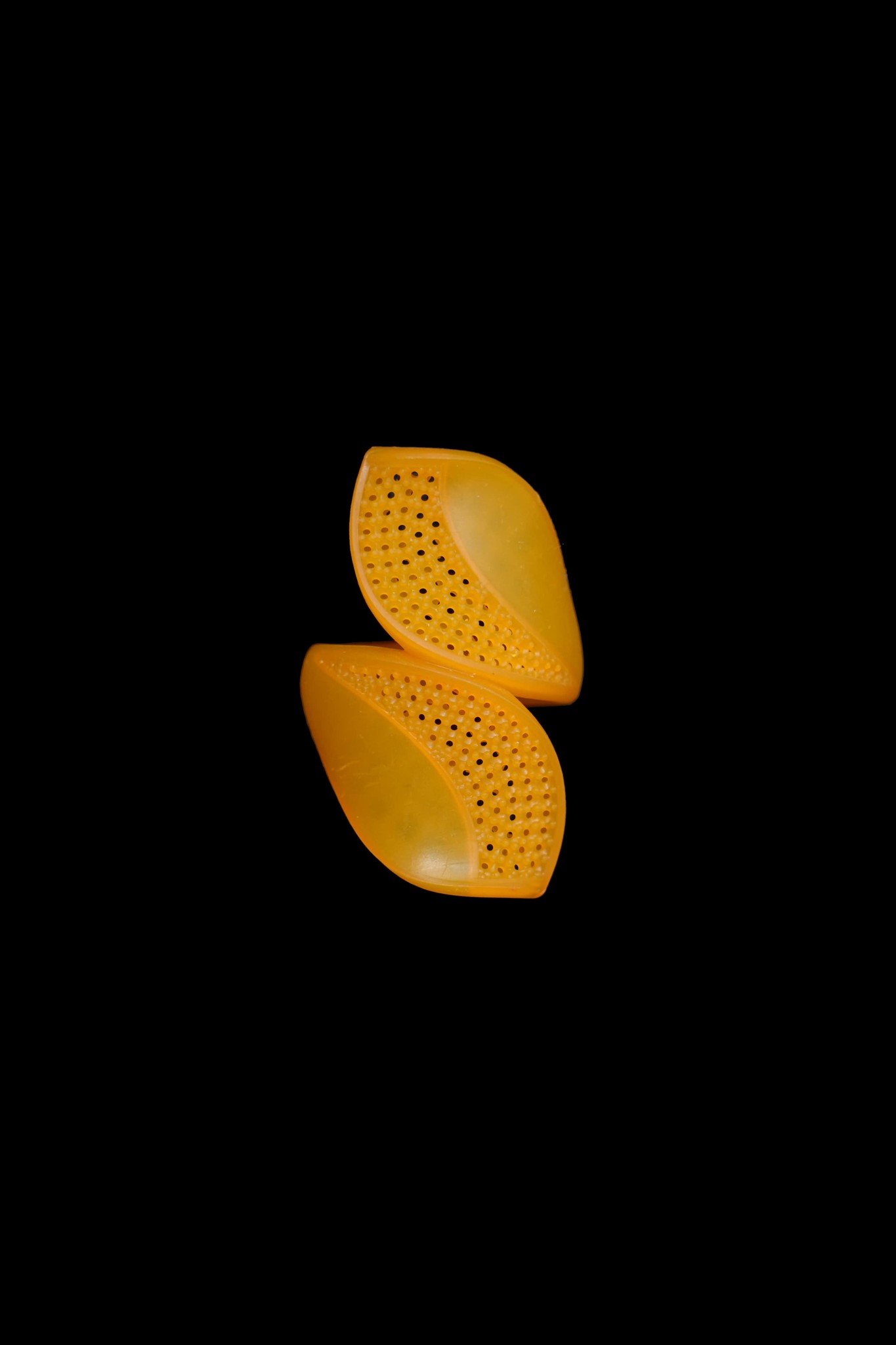

DCDNO & DCDNR - are universal casting resins which can be used for all designs of jewellery, from fine filigree wires to solid men's rings and plain surfaces.

They are both similar formulations however, DCDNO casts a little better but DCDNR prints a little sharper and is more suited for diamond jewellery.

This universal jewelry resin is immensely popular because of its versatility in terms of usage. Not only does it offer the finest casting quality, these resins are easy to use as well.

Features :

Universal resins for all types of jewellery

Top casting quality

Easy burnout

Can use normal investment powder

Shrinkage less than 1%

Properties :

Tensile strength: 23 Mpa

Flexural strength: 47 Mpa

D shor hardness: 63

Can use normal investment powder

Viscocity: 700 to 800 Mpas @ 24°C

Post Processing Instructions:

Recommended Burnout Cycle :

Step 1

Room Temp to 100°C

Ramp @ 2°C/minute = 30 mins

Hold Time: 3 hours

Total Time: 3 hours 30 mins

Step 2

100°C to 730°C

Ramp @ 5°C/minute = 2 hours 6 mins

Hold Time: 4 hours 30 mins

Total Time: 6 hours 36 mins

Step 3

730°C to Cast Temp

Aprox 30 mins

Hold Time: 1 hour 30 mins

Cast

Total Time: 2 hours 30 mins